The heat shrink tube is an essential tool in electrical, wiring and industrial maintenance installations. Thanks to its adaptable design, it offers multiple solutions in protection, insulation, identification and aesthetics of cables and connections. In this article, we discuss the main uses of heat shrink tubing, its benefits, and how to apply it correctly.

Main Uses of Heat Shrink Tubing

1. Electrical insulation

One of the most common uses of heat shrink tubing is conductor insulation. When applied over a bare wire or joint, it forms a strong barrier that prevents short circuits, current leakage and accidental contacts.

2. Mechanical protection

The heat shrink tube protects joints, welds and joints from scratching, vibration and mechanical stress. Extends the life of electrical components even in demanding industrial environments.

3. Resistance to external agents

Many heat shrink tubing models offer resistance to:

- Humidity and water

- Oils and chemicals

- Extreme temperatures

This makes it the ideal choice for outdoor installations or industrial environments.

4. Cable Management

By bundling multiple wires, the heat shrink tubing facilitates a cleaner and tidier installation. It also helps to reduce tensions at the connection points, improving the durability of the system.

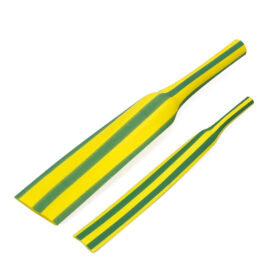

5. Identification and Coding

Thanks to its availability in various colors and printable formats, this tube allows you to mark phases, functions or specific areas of the electrical system, optimizing maintenance and safety.

6. Aesthetic improvement

In electronics, DIY, or visible installation projects, heat shrink tubing helps to unify cable finish, hide imperfections, and achieve a professional presentation.

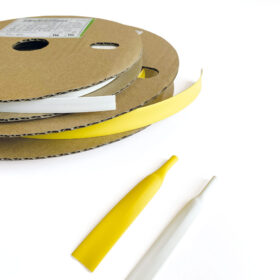

Types of heat shrink tubing according to their use

There are different types of heat shrink tubing adapted to each need:

- Thin-walled or thick-walled: for standard or mechanically demanding applications.

- With inner adhesive: airtight sealing and superior resistance.

- Printable tubes: ideal for labeling and marking.

- Clear or colored tubes: for quick visual identification.

- Special materials: such as polyolefin, elastomer or Teflon, which offer greater thermal or chemical resistance.

How to apply heat shrink tubing step by step

- Cut the tube to the desired length, considering the shrinkage.

- Insert the cable or element into the tube.

- Apply heat with a heat gun until the tube fully contracts and adheres to the contour.

This process ensures safe, long-lasting, and professional coverage.

Conclusion: A versatile solution for professionals and technicians

The multiple uses of heat shrink tubing make it an essential resource in any electrical installation. From insulation and protection to organization and aesthetic improvement, its versatility positions it as a tool of high technical value.

In XB Components We have a complete range of heat shrink tubes with different diameters, thicknesses and materials, adapted to each application.

XB Components, a leader in the electrical components industry, is recognized for our commitment to quality and customer service. Our mission is to provide innovative and high quality solutions that meet the needs of our customers.

Subscribe to our newsletter

Subscribe to our newsletter

We will inform you about news, promotions, events...