Crimping tools are essential in many electrical and mechanical jobs, and their safe use is critical to ensure optimal results and avoid accidents. In this article, we will guide you on how to use crimping tools safely, addressing best practices and tips to maximize efficiency and safety.

What are crimping tools?

Crimping tools are used to join electrical conductors with cables, ensuring firm and durable connections. They can be manual, hydraulic or electric, and each type has its own applications and safety precautions.

Preparation before using crimping tools

Tool inspection:

- Before starting, check that the crimping tool is in good condition. Look for signs of wear, damage or missing parts.

- Make sure that all moving parts are working properly and that the crimping accessories are in optimal condition for use.

Selection of the appropriate tool:

- Use the proper crimping tool for the type of cable and connector you are using. The tool specifications must match those of the job to be done.

- Consult the manufacturer's manual to confirm that you are using the correct tool for the task.

Personal protection:

- Wear personal protective equipment (PPE), such as gloves and safety glasses, to protect yourself from possible cuts or flying fragments.

- Be sure to work in a well-lit and uncluttered area to avoid trips and accidents.

How to use a crimping tool

- Correct positioning:

- Place the terminal in the correct position inside the crimp dies. Make sure that the connector is properly aligned to avoid incorrect crimps.

- Insert the wire into the terminal firmly and make sure that all wire strands are inside the terminal before crimping.

- Force application:

- If you are using a hand tool, apply even and steady pressure until crimping is complete. Avoid squeezing sharply to avoid damaging the terminal or the tool.

- For hydraulic or electric tools, follow the manufacturer's instructions on how to activate and operate the tool. Make sure the tool is set up correctly for the type of crimping you are performing.

- Verification of crimping:

- After crimping, inspect the connection to make sure it is tight and secure. There should be no movement of the cable inside the connector.

- Perform a pull test to confirm the integrity of the connection. If the cable comes loose or the connector is deformed, repeat the process using a new connection.

Maintenance of crimping tools

- Regular cleaning:

- Keep crimping tools clean and free of debris. Use a soft brush and a clean cloth to remove any dirt or debris.

- Lubricates the moving parts of the tool to ensure smooth operation and prolong tool life.

- Adequate storage:

- Store crimping tools in a dry and protected place to avoid corrosion and deterioration.

- Use specific tool cases or covers to keep tools organized and protected when not in use.

- Periodic inspection:

- Periodically inspect your crimping tools for wear or damage. Replace any defective components immediately.

- Consider calibrating your crimping tools regularly to ensure they continue to perform accurately.

Knowing how to use crimping tools safely not only ensures the quality of your connections, but also protects your well-being. Follow these tips and best practices to ensure that your crimping jobs are efficient, durable and safe. Remember to always follow the manufacturer's instructions and keep your tools in optimal condition to prolong their life and ensure professional results.

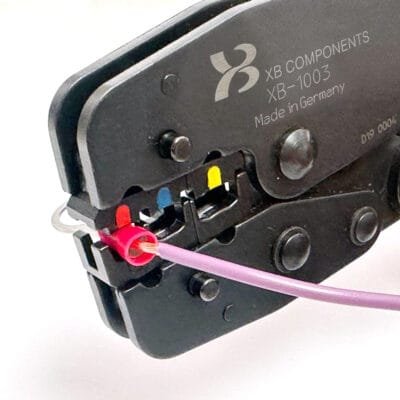

For those seeking the best combination of quality and safety, we recommend XB Originals crimping tools. These tools are designed to offer exceptional durability and superior performance in every use. With a focus on ergonomics and precision, XB Originals crimp tools ensure strong, long-lasting connections, making your job easier.

With XB Originals crimping tools, you will take your projects to the next level safely and efficiently. See our catalog for more information.

XB Components, a leader in the electrical components industry, is recognized for our commitment to quality and customer service. Our mission is to provide innovative and high quality solutions that meet the needs of our customers.

Subscribe to our newsletter

Subscribe to our newsletter

We will inform you about news, promotions, events...